The global textile industry faces the great challenge of rethinking its proven products and processes in order to redesign them in line with sustainable criteria. PrimaLoft, Inc. a leading expert in the development of innovative material technologies, began years ago to push the boundaries of materials science in order to offer more sustainable products. The declared goal: a perfect balance between performance and responsibility.

After four years of development, the company presented PrimaLoft Bio in autumn 2018, the world's first biodegradable, 100% recycled synthetic fibre. Thanks to a special treatment of the fibres, they decompose much faster than conventional polyester under the conditions of a landfill or sea water and are completely biodegradable.

The decomposition process leaves behind only natural elements: Water, methane, carbon dioxide and biomass. PrimaLoft has thus found a solution to the urgent problem of environmental pollution caused by microplastics and an answer to the question of how a textile can be sustainably disposed of at the end of its life cycle. In autumn 2020 the first PrimaLoft biodegradable products from brands such as Jack Wolfskin, Maloja, Norröna, Reusch and many others will be on the market for the first time.

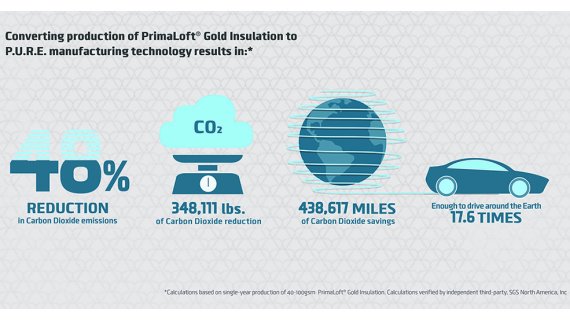

At the end of 2019, PrimaLoft announced a breakthrough in manufacturing technology that will lead to a significant reduction in carbon dioxide emissions: PrimaLoft P.U.R.E. is the term for a new standard in the production of insulation fibers. In the past, the fibres were heated in order to bond the fibres together. With the new process, this can be done with air alone.

This can reduce annual carbon dioxide emissions by up to 48 percent. The first insulation product manufactured using P.U.R.E. manufacturing technology also uses 100 percent post-consumer recycled material and has all the insulation and performance advantages of the existing PrimaLoft Gold insulation.

In fall 2020, Patagonia will be the first brand partner to introduce PrimaLoft P.U.R.E. manufacturing technology in its world-renowned Nano-Puff program.

2019 also saw the start of the strategic partnership between PrimaLoft, Adidas and Parley for the Oceans. The environmental organisation Parley for the Oceans aims to reduce the pollution of the seas by plastic waste by collecting and recycling plastic waste from beaches and the sea.

As part of the cooperation, PrimaLoft has developed a special process that enables the company to manufacture insulation products from marine plastics that meet the company's high performance standards. PrimaLoft is the first insulation materials supplier in the textile industry to work with Parley to create new products from marine plastics. As a first step, Adidas will use the new high-performance insulations for its own collection.

Since 2015, PrimaLoft has already used more than 6.6 million kilograms of recycled material in its Eco products and recycled more than 266 million plastic bottles. But recycling alone is not enough.

The long-term goal of PrimaLoft's sustainable commitment is the establishment of circular production processes so that raw materials can be recycled as often as possible. PrimaLoft Bio is groundbreaking in this respect: the recycled synthetic fibre is not only biodegradable, but also ready for use in a circular economy, i.e. it is itself recyclable.

*93.8 percent biodegradation in 586 days under ASTM D5511 conditions (landfill environment); 65.5 percent biodegradation in 639 days under ASTM D6691 conditions (seawater environment). The stated speed and extent of degradation does not mean that the product will degrade further.

PromotionOpens lens – tools for true impact

PromotionOpens lens – tools for true impact

- Awards

- Mountain sports

- Bike

- Fitness

- Health

- ISPO Munich

- Running

- Brands

- Sustainability

- Olympia

- OutDoor

- Promotion

- Sports Business

- Textrends

- Triathlon

- Water sports

- Winter sports

- eSports

- SportsTech

- OutDoor by ISPO

- Heroes

- Transformation

- Sport Fashion

- Urban Culture

- Challenges of a CEO

- Trade fairs

- Sports

- Find the Balance

- Product reviews

- Newsletter exclusive area

- Magazine