Waterproof jackets are the epitome of outdoor clothing. It was only when Bob Gore discovered the possibilities of stretched PTFE for the production of breathable and waterproof membranes in 1969, thus laying the foundation for Gore-Tex, that the outdoor clothing segment and trade developed into a huge international growth market. There are now numerous other technical solutions and suppliers that make clothing waterproof and breathable. However, as indispensable as waterproof jackets are in the outdoor market today, they are also problematic for the environment.

Waterproof outdoor jackets consist almost exclusively of petroleum-based outer fabrics (e.g. polyester) laminated with a petroleum-based membrane. In the case of Gore-Tex, for example, with a membrane made of PTFE or the new ePE membrane made of polyethylene. Once bonded together, the outer fabric and membrane cannot be separated again, which makes recycling considerably more difficult. "Gore-Tex laminates are not yet recycled," says Hannu Haslach from the Gore Fabric Marketing team. And as long as recycling is not yet available, these jackets end up either in waste incineration or in landfill, where they take centuries to decompose. Considering how many of these jackets come onto the market every year, that's a lot of waste for the future.

In addition, waterproof jackets require a water-repellent finish on the outer fabric, also known as DWR (Durable Water Repellency), so that the fabric does not become saturated and thus impair breathability. Until a few years ago, almost 100 percent of these DWRs were made of polyfluorocarbon, better known as PFC or PFAS. This abbreviation stands for a group of chemicals that are at least suspected of being harmful to health and the environment, which is why Greenpeace has been campaigning against them for years and the EU is considering a ban. It has taken a long time to find an equivalent and environmentally friendly alternative to PFCs - and it has still not been completely successful. PFCs are therefore still used in workwear and protective clothing. But the good news is that the outdoor industry has now largely banned them from its products.

If there are no recycling solutions yet and no rapid progress is expected in the development of more sustainable materials, what could a solution look like that would make a waterproof jacket more sustainable? How can the ecological footprint of such a high-tech jacket be reduced? In a life cycle analysis, W.L. Gore found that 65 percent of the CO₂ footprint is attributable to production, around 34 percent to the use phase and one percent to the end of life. Making materials and production facilities more climate-friendly therefore has a major impact. "But the industry is producing more and more products, often with less and less quality, which are used by consumers for shorter and shorter periods of time," says Marie Mawe, Director Sustainability Engagement of the Gore-Tex Fabrics Division. "This automatically increases pollution and waste. Even if the ecological footprint of our clothing improves step by step during production, the sheer volume of new products will outweigh this positive effect." The most effective approach would therefore be to produce fewer items of clothing and extend the useful life of the products.

It is not only the EU's Ecodesign for Sustainable Products Regulation (ESPR) that requires clothing to last longer, more and more outdoor brands are also developing strategies to ensure their products can be used for longer. This starts with "Design for Durability" and includes not only product quality and the materials used, but also the provision of detailed care instructions, the guarantee of repairability and repair services through to the sale of second-hand products.

When it comes to product care, waterproof jackets still have a lot to do. "Some people believe that a Gore-Tex jacket should not be washed, but the opposite is true," says Sander Effring, Account Marketing Specialist at W. L. Gore. In order to maintain full functionality for a long time, the jackets must be washed regularly and cleaned of dirt, sweat, sun cream etc.. This also washes out the DWR over time, which needs to be reactivated with heat (in the dryer or with an iron) or refreshed by re-impregnating. "Care is becoming increasingly important for everyone," says Hannu Haslach, referring to the new DWRs. "There is no longer such a strong treatment as we had with the PFC DWRs. New DWRs are more susceptible to sweat and grease, which is why they are not yet an alternative for protective clothing." It is therefore becoming increasingly important to care for a waterproof jacket correctly so that it retains its function and is used for as long as possible. This applies not only to waterproof jackets, but also to soft shells and water-repellent textiles without a membrane. They will all require more care in future in order to last longer.

At Gore, questions about the care of Gore-Tex products have been among the three most frequently asked questions by customers on the international service hotline for decades. Videos with care instructions also regularly achieve high click rates on the website and in social media. This also applies to brand partners and retailers, who are now focusing more on this topic. "Gore, as well as retailers and the industry, must pass this knowledge on to consumers," says Haslach. That's why proper care has long been part of training courses for sales staff in retail and for brand partners.

Gore further strengthened its commitment two years ago with the launch of the "Gore-Tex Gear Tour": Gore tours Europe and cooperates with retailers to educate consumers about the care of Gore-Tex products and repair products on site. The company has also established partnerships for the repair of Gore-Tex products and set up 35 officially certified Gore-Tex repair centers. If the repair is carried out there, the "Guaranteed To Keep You Dry" promise remains valid.

The intention to bring more durable and longer-lasting products onto the market so that fewer new products need to be purchased is understandable and correct. It is more difficult to find a definition of what durability actually means so that this term can be brought to life in future European legislation, for example. There is currently no method for measuring the shelf life of products, even though it is the key to a more sustainable industry. In spring 2023, Mittuniversitetet in Sweden initiated a global research project with the aim of creating a common industry standard measurement that takes product function and performance into account.

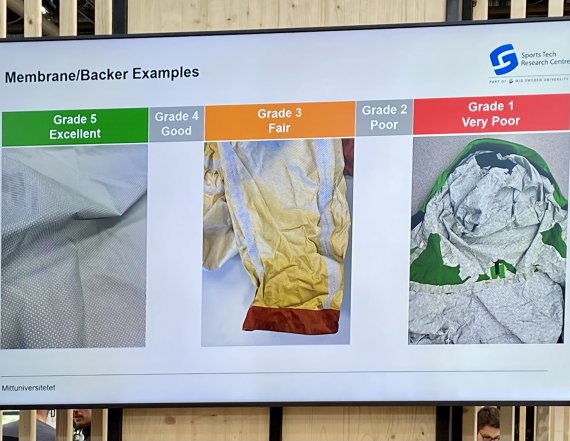

"We understand very well when a product fails in the early phase of use, because then the warranty case occurs and the product is complained about. Then the manufacturers get the product back and can draw conclusions for improvements. But we know very little about which criteria lead consumers to throw away a product after many years," said Dr. Judith Waller, Louisa Nilsson and Isabell Vorne from the Sports Tech Research Centre at Mittuniversitetet in their presentation at the last OutDoor (3 - 5 June 2024 in Munich).

Using 318 discarded waterproof jackets from different manufacturers that consumers have given to the researchers, the team wants to determine which functional aspects users consider to be the cause of the end of the service life and compare these with the defects the clothing actually had. After all, it is not only objective, purely functional criteria that determine useful life. Subjective, emotional aspects such as aesthetics, brand identity or comfort are just as important. The aim is to develop a test protocol for measuring the durability of jackets that reflects actual use.

The research work is not due to be completed until 2026. However, the evaluation of the jackets shows that the condition of the jackets sent in varied greatly, with 2.5-layer jackets, for example, being in a particularly poor condition. In general, the neck, hood and front areas showed the most defects and signs of wear. The industry could derive specific opportunities for improvement from this. But here too, product care remains a key lever and the help of consumers is essential. "The question that has already emerged from our results so far is whether the deterioration of the product could be prevented by avoiding care errors and through better care. It would be good if we could reduce the number of these errors," says Judith Waller. She therefore also wants to find out at what point you would have to intervene in order to improve the shelf life through proper care.

- Awards

- Mountain sports

- Bike

- Fitness

- Health

- ISPO Munich

- Running

- Brands

- Sustainability

- Olympia

- OutDoor

- Promotion

- Sports Business

- Textrends

- Triathlon

- Water sports

- Winter sports

- eSports

- SportsTech

- OutDoor by ISPO

- Heroes

- Transformation

- Sport Fashion

- Urban Culture

- Challenges of a CEO

- Trade fairs

- Sports

- Find the Balance

- Product reviews

- Newsletter exclusive area

- Magazine